Master Bond epoxies exhibit outstanding physical strength properties for high performance bonding, sealing, coating, potting and encapsulation. In the lab, we continually test the bond strength of our materials using a variety of methods. A typical performance assessment is called lap shear testing.

Lap shear is one of the most common stresses that a bonded joint can face during service, especially in structural bonding applications. The lap shear strength of an adhesive serves as one of the indicators for its long-term survival in an application.

When performing lap shear testing, two flat surfaces are bonded, and a force is applied along the plane of the surfaces until failure. The maximum force exerted is referred to as lap shear strength. Such testing allows us to more accurately recommend the right adhesive based on specific application requirements.

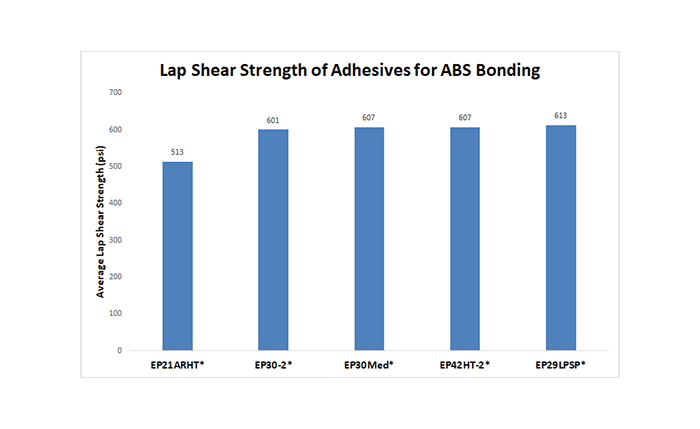

Evaluation for this property is based on the ASTM D1002 test procedure and is typically performed for an aluminum to aluminum bond joint. However, in this specific experiment, the focus was on testing the strength of our epoxies when bonding ABS to ABS. This bonding was done using coupons measuring 4 x 1 x 1/16 inch to mimic the coupons in the standard lap shear test procedure. The surfaces were mechanically abraded and cleaned with isopropyl alcohol prior to dispensing the product. Each sample was processed and cured according to its specifications. It is important to note that the proper surface preparation and cure schedule play a pivotal role in achieving the highest possible bond strength. The compounds we used for testing are two component epoxies with good overall strength properties: EP21ARHT, EP30-2, EP30-Med, EP42HT-2, and EP29LPSP.

Lap shear strength testing results for these diverse Master Bond epoxy adhesives are shown in the table below. For all the products tested we noted substrate failure meaning that one of the ABS coupons broke before the bond. This indicates that all these products exhibited a strong bond to ABS and that it is not a particularly challenging substrate to get good adhesion with. However, close attention must still be paid to proper surface preparation, fixturing while curing, proper measuring as well as mixing and ensuring that the product is fully and properly cured.

Each of these epoxies has its own distinctive advantages. For example, EP29LPSP is also serviceable at cryogenic temperatures while EP42HT-2 offers exceptional resistance to many chemicals, EP30MED passes the USP Class VI requirements for biocompatibility, EP21ARHT has excellent acid resistance, and EP30-2 has outstanding outgassing properties.

Determining the most suitable bonding agent is dependent not only on strength properties but also meeting specific processing and service conditions for the mated ABS surfaces. Therefore, it is important to point out that while these compounds were some of the products selected for this study, Master Bond offers several custom formulations and based on the unique requirements of each individual application, other products may be excellent fits as well. For more information on Master Bond high strength epoxy adhesives, please contact our technical advisors.

Graph 1

Disclaimer: The findings in this article are not meant to be used for specification purposes.

Lap Shear Strength Adhesives for ABS

|

EP21ARHT Serviceable from +400°F. Exceptional acid resistance. Cures at room temperature. Good flow properties. 100% reactive. Low shrinkage upon cure. |

|

EP30-2 Cryogenically serviceable. NASA low outgassing approved. 100% reactive. Excellent light transmission properties. Outstanding dimensional stability. High tensile and compressive strength. Successfully tested for 1,000 hours 85°C/85% RH. Excellent dielectric properties. Serviceable from 4k to +300°F. |

|

EP30Med Biocompatible two component epoxy. USP Class VI approved. Low viscosity. Versatile cure schedules. Resists EtO, gamma radiation and cold sterilants. High strength rigid bonds. Serviceable from -60°F to +250°F. Can be used for indirect food contact per 175.105 FDA specification. |

|

EP42HT-2 Bonding, sealing, coating, potting compound. Heat, chemical, steam resistant. Superior optical transmission properties. Solvent free. Withstands exposure to acids, alkalis and many solvents. Castable up to 2-3 inches. Cures readily at ambient temperature. Service temperature range -60°F to +450°F. |

|

Two component, low viscosity, modified heat cured epoxy system for bonding, sealing and coating. Formulated for service at cryogenic temperatures and capable of withstanding cryogenic shock. Meets NASA low outgassing requirements. Optically clear. |